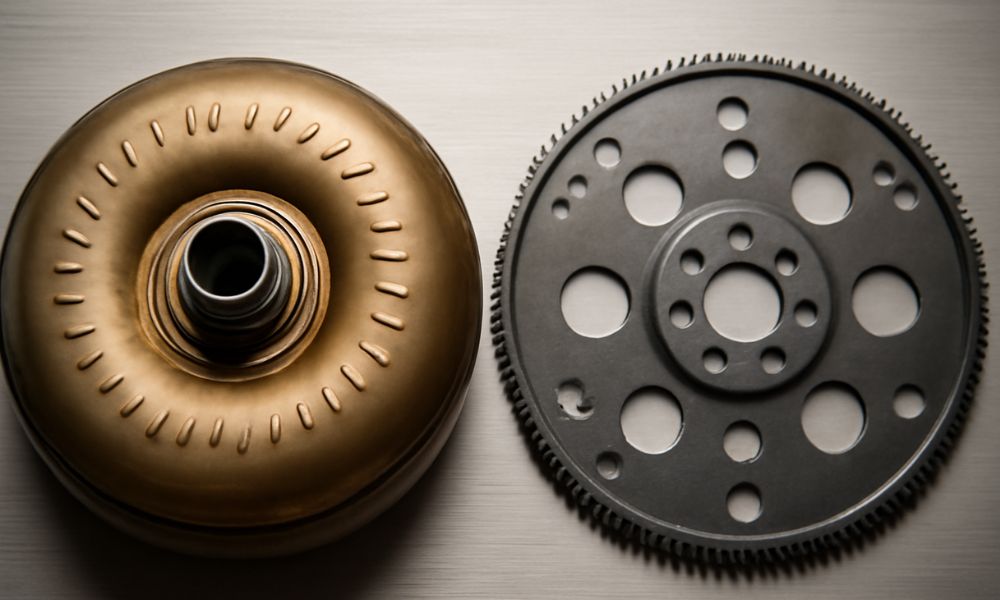

In the world of automotive mechanics, subtleties can get lost in the shuffle, but not the clearance between the torque converter and the flexplate. This small space makes a world of difference in how your car’s transmission operates. The torque converter, along with the flexplate, is responsible for transferring the rotating engine power to the transmission. But if they are misaligned, even slightly, trouble begins. This relatively minor detail can precipitate a series of failings, from low shift feeling to full-scale transmission meltdown. So, what’s the secret? Making sure the torque converter-to-flexplate clearance is exact before installing is vitally important. But how, exactly, does this gap work, and what if it gets it wrong? Let’s dive in.

What If You Get Clearance Wrong?

You can almost picture it now: the converter and the flexplate are just sitting there–almost touching one another–waiting for everything to be aligned just so to operate in harmony like some well-tuned orchestra. When the clearance is not quite right, the music sags. If it’s too close, the torque converter might come into contact with the flexplate, causing friction, heat, and possible failure. Now think the reverse: It’s too spread out.

Even that can lead to a loss of power transfer efficiency and contribute to poor acceleration, bad engine performance and possibly torque converter slip. It’s a no-win scenario. The trick is the precision, because even the tiniest deviation in the clearance increases the risk of serious damage and expensive repairs in the future.

Torque Converter to Flexplate Clearance Specifications

The perfect clearance does depend on the vehicle, and your car is no different. The distance from the torque converter to the flexplate should normally be 0.080 to 0.160 inches. Those specifications can usually be found in the service manual of the vehicle and must be followed to the letter to ensure the best possible results. Too much clearance? You’re looking at poor efficiency. Too little? Oh well, you know the results. So it’s important to take the right tools and techniques so that the gap remains within these carefully prescribed limits.

How a Torque Converter and Flexplate Work Together

To appreciate why this clearance is important, you need to understand what these parts are up to. The torque converter serves the critical function for the powertrain; it’s what literally connects the output of the engine to the input of the transmission. It employs hydrodynamics to transmit power, providing even shifting among the gears. The flexplate, a thin but resilient disk of metal, takes up vibrations as it couples the torque converter and the engine’s crankshaft. These parts combine to form a smooth system, which allows the movement of your car. “But if that delicate balance gets disrupted, for example, by incorrect clearances, things go very wrong.”

Measuring the Torque Converter-Flexplate Gap

The delicate art of measuring this critical gap is a hard one. Here’s how that works: Start by using a feeler gauge, a small, flexible tool that enables you to measure small gaps precisely. Insert the gauge between the torque converter and the flexplate. You may have to rotate the flexplate to make adjustments so the gap runs equally around the flexplate. They shouldn’t need to be pried apart; just let the gauge slide in with a good, snug fit. If your measurement is within the range, it’s all good. If it doesn’t, you need to make some changes.

Typical QS&D: Torque Converter to Flexplate Clearances

Anything can happen during this process. Plenty. One of the most frequent problems is displacement. If the torque converter is not centered as it should be, you will have uneven wear and potential damage. Likewise, if the bolts are not torqued correctly, they can interfere with the clearance and produce vibrations, noise, or even a catastrophic failure on one or more components. The build-up of torque on the bolts also has to be just right, not too tight or loose, as that too can lead to misalignment.

Variation That Impact Torque-Converter-To-Flexplate Clearance

It’s not only the specs themselves that can mess with steering clearance requirements. External forces such as worn engine mounts, modifications, and even the car’s weight can affect the gap. Engine mounts that have been in service for a long time can allow the alignment of the torque converter-to-flexplate to run out, and a new clutch or an engine swap, like Teutonic Storm, which came with the former engine, a 1998 4.6 Mustang, may complicate matters further. So it is good to have these factors in mind when setting and adjusting the clearance.

Torque Converter Installation/FlexPlate Clearance

The torque converter installation is where you make absolutely certain everything’s oriented properly. The torque converter will be centered just slightly to the front in the correct gap that must be maintained at the flexplate. Take your time, keep the mounting bolts evenly tensioned. Precision here is key (tightening), spread some of the same white slick on the splines and inside the crank. And don’t rush.

Dialing In The Torque Converter-to-Flexplate Gap

For that ever elusive perfect gap, carefully use a feeler gauge, adjust accordingly and refer to the manufacturer’s recommended settings. Although you might want to rush the installation, don’t forget: this step can be the one to make or break your car’s performance. Double-check your measurements and tighten bolts only after you’re sure all is where you want it.

Signs You Need to Re-Check Torque Converter-to-Flexplate Clearance

You can also keep your eyes out after the fix. Odd noises, grinding, whining or too much vibration can be indications that the torque converter and flexplate are not centered correctly. Poor acceleration, shifting problems or even power loss could also be a sign of the clearance being out. If any of these symptoms appear, it’s time to re-evaluate the clearance and make changes.

Preventing Errors during Torque Converter Installation

When rushing to install, we notice the easiest mistake to make is aligning too quickly. A shortcut here can mean imminent failure there. Make sure the torque converter is aligned impeccably, and not slipshod on bolt tightness. Do not become so pressed for time that you bypass important work.

The Role of Professional Mechanics

Not everyone can address the converter-to-flexplate clearance themselves. If you’re not sure how to do it or don’t have the correct tools, consider having a professional do it for you. They can offer the expertise to ensure everything is in perfect order, as well as spot any problems that could conceivably spiral into larger concerns.

Maintaining Proper Clearance Over Time

It is important to continue to regularly inspect and service your torque converter and flexplate even after installation. Normal wear, vibration or any deviation in powertrain performance may indicate the clearance needs to be adjusted. Listen for unusual sounds and keep up with regular maintenance to prevent problems down the road.

Related Post: How to Test a Torque Converter Overrunning Clutch Without a Machine

Conclusion

The distance between your torque converter and flexplate may appear to be irrelevant, but the truth is, it’s an important aspect of your vehicle. When the alignment is right, everything can be in proper working order and little or no appliance wear will occur. (4 feet) between guards in accordance with manufacturer instructions and check frequently. The result? A vehicle whose engine performs as it’s meant to. Protecting your powertrain parts and your wallet from any unexpected money grabs.