What do you think of when you hear the words torque converter? A confounding, almost cult-like tool tucked deep inside the clandestine society of automotive engineers? Perhaps. But there’s a catch: this frequently underappreciated wonder is essential to the smooth and efficient functioning of automatic transmissions. Without it? The latest generation of trucks would be no good at their most fundamental jobs, say, accelerating smoothly or shifting gears effortlessly.

Now, don’t just shrug it off. In this post, we lift the cover and take a deep dive into the basic components & parts of a torque converter. Stay with me, readers or car enthusiasts who simply want to know more about how your vehicle operates. You’ll learn all the ins and outs of every component that goes into this key system.

The Basic Structure of a Torque Converter

At its core, a torque converter is a hydraulic transmission device (like the pump in a hydraulic brake system) that serves to transmit power from the engine to the transmission. You can’t see it, but there’s an unseen force (or pressure) of sorts that moves rotational power through the engine and switches gears in your transmission so that your car has its fluid running motion (also known as operating smoothly). It’s not one thing; rather, a symphony of components each playing its own, finely tuned role to maximize power transfer, manage speed and preserve fuel efficiency.

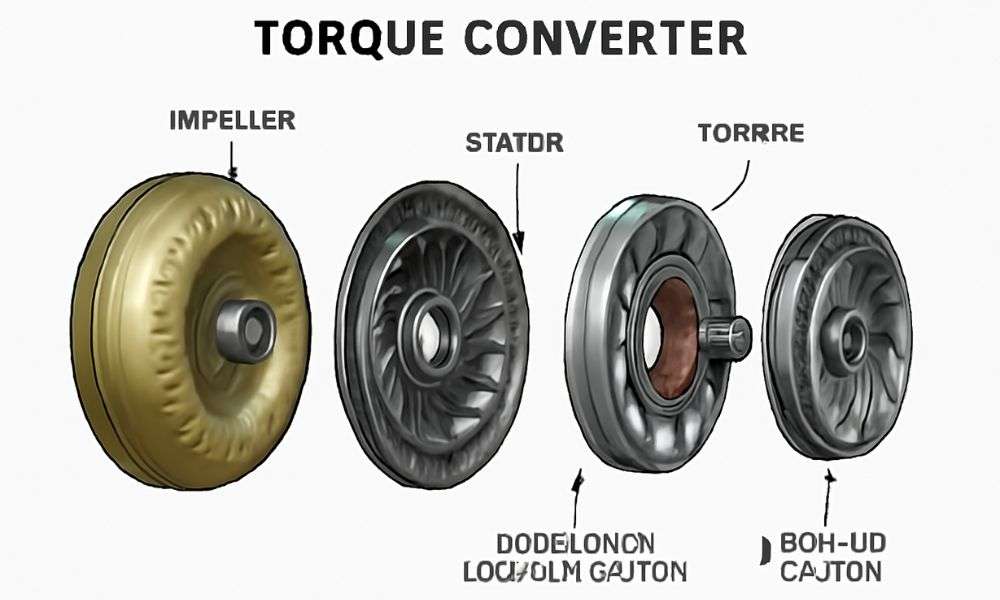

This cooperative assembly includes the impeller, turbine, stator, lock-up clutch and yes, transmission fluid working together in roles you may not have heard of before. Knowing the configuration of a torque converter is critical to understand how these components interact with one another for optimal efficiency.

Inside a Torque Converter: Components in Action

There, inside the torque converter, fluid dynamics performs an intricate dance with mechanical design. The converter system itself is comprised of this nifty manipulation of blades and chambers that are all designed to use the rotational energy of the engine to promote flow, which in turn causes the power. So imagine this: As the engine turns the impeller, it’s forcing fluid towards the turbine that drives it toward the transmission.

Meanwhile, the stator’s a cunning devil and sends liquid back to the impeller instead, looping that fluid is! That’s where the lock-up clutch comes in–locking everything together at higher speeds to prevent slip and maximize the power delivery. Each one of these elements within the overall framework is utterly dependent upon all the rest; a slight breakdown of one part and the disparate parts dissolve into nothing but chaos.

What are the Components & parts of a Torque Converter?

Now, let’s break down the main parts of a torque converter. Every single one is needed, and every single one performs a specific function to make sure that the entire system functions as designed:

- Impeller: This is the force that gets its power directly from the engine.

- Turbine: This is the part that takes and extracts fluid from the impeller and provides power to the transmission.

- Stator: This bit of directional wizardry redirects fluid to the most efficient part of the jet pump.

- Lock-Up Clutch The lock-up clutch is designed to unlock at lower speeds for smoother low-speed driving and lock up at higher speeds for a more secure direct engine-to-transmission connection.

- Transmission Fluid: The hydraulic system that makes the transfer of power by using fluid to move through the working parts and keeps all those sophisticated inner parts switching without catching.

As a whole, these parts work as a smooth-running, balanced system – every piece with its own role in power transfer.

The Impeller: The Torque Converter’s Heartbeat

The impeller is said to be the “heart” of a torque converter and this is an accurate description. It’s the heart-starter, the ignition that starts the power flowing from the engine. It is bolted to the flywheel of the engine and made up of blades that rotate with the engine. As the impeller rotates, it throws transmission fluid at the turbine. This isn’t mere fluid action; this is raw kinetic energy converted into entrained fluids, ready for power transfer. Without the impeller, this would be a solid piece of metal and the entire torque converter would stop rotating. It’s the bread on which everything else is built.

The Impeller, Stator and Turbine: The Holy Trilogy

The relationship of the impeller, stator, and turbine is fundamental to the operation of the torque converter. Call it a power trio. It has a rotating impeller that sends fluid out toward the turbine. The vehicle’s transmission, then, uses that mechanical energy to power up the turbine. Now enter the stator. Once placed between the turbine and impeller, it redirects that fluid and hurls it back towards the impeller with even greater force. When everything comes together as a whole, efficiency is then maximized. These parts combined form an energy loop that keeps a vehicle sailing quietly and smoothly down the road. If one thing stops working, everything else can go awry.

The Turbine: Power Transmission on the Move

The turbine is where the action happens; it’s pressed up against the converter housing and moves with it as a result of fluid pressure, and so is part of whatever torque-spinning action affects that housing. At the other side of the impeller sits the turbine, ready to accept the fluid force fed into it. When the fluid hits these blades, it makes them spin. This turning is transmitted to the car’s transmission and ultimately drives its drive train. The greater the speed of the turbine, the more power it transmits to the wheels. It’s the part that links the engine’s unadulterated rotational energy to the wheels, ensuring that a vehicle is capable of maintaining speed and performance.

The Stator: An Unsung Hero for Torque Converter Efficiency

In the shadows, and typically ignored, is the stator; however, without it, a torque converter would be nothing more than an inefficiency-generating contraption. Located between the impeller and the turbine, the stator redirects fluid flow after going through the turbine so it can be returned to the impeller. The stator effectively re-energizes the fluid, increasing its velocity as it feeds back into the impeller. This, as a result, means the torque converter operates with limited energy waste. It’s an unheralded, unsung hero in the pursuit of maximum torque multiplication. Without it, the entire system would be much less efficient and performance would lag.

The Lock-Up Clutch: High-Speed Accuracy

At higher speeds, a vehicle’s torque converter fluid coupling can cause efficiency loss. Why? As the engine and transmission are not linked directly. This is where the lock-up clutch comes in. It engages the turbine to the engine flywheel, preventing slippage and creating a solid link between the output of the engine and the input shaft of the transmission. The result? More efficiency, more fuel economy, less heat! This is particularly crucial to maintain high-speed cruising, wherein direct drive is a must for a seamless ride.

Fluid Coupling and the Transmission Fluid from there

Fluid coupling is fundamental to the behavior of a torque converter. Transmission fluid is the fluid that transfers the power from the engine to the pavement. It’s the element that goes unheralded, facilitating the transfer of rotational energy between the engine and transmission without mechanical contact. Transmission fluid quality is critical to performance. When the fluid becomes dirty or breaks down, performance suffers as temperatures rise and parts may fail. Regular fluid maintenance and checkups for the torque converter prevent your transmission system, and by extension your whole car, from failing or breaking down.

Troubles that may Signal Torque Converter Problems

The torque converter, like any mechanical device, is subject to problems and can malfunction. Typical complaints are slipping, overheating, and lock-up clutch failure. In case the converter is slipping, you might feel late or hard shifts and poor acceleration. Low-quality fluid or being low on fluid is not the end-all, be-all cause of overheating, though. If the lock-up clutch goes bad, you might get a vibration or shudder while driving at high speeds. Identifying some of these symptoms early can stop the wear and tear on your car at its prime. Read more.

Symptoms of a Bad Torque Converter

Knowing how to recognize the symptoms of a bad torque converter can help you maintain your car’s performance. Here are some red flags to look out for:

- Sluggish or lack of response to gear change

- Unusual whining or grinding noises

- What were the shuddering or vibrations on the highways

- Excessive Engine or Transmission Oil Temperature

If you’re experiencing any of these issues, it’s crucial to get your torque converter inspected and repaired sooner rather than later in order to avoid the possibility of more problems developing down the line.

Conclusion

The torque converter is a mechanical engineering wonder part of the drive train that receives little recognition despite its importance. With an understanding of the sophisticated nature of a CVT and how it works, motorists can easily see just how much these parts promote smooth acceleration, peak engine operation, and effective power displacement. Keeping up on your fluid exchanges and other maintenance, as well as checking fluids regularly, can help keep that torque converter calibrated properly, which will help your vehicle continue to serve you for many years.